Fiber reinforced plastic, or FRP, has long been a popular choice for wall coverings in commercial, industrial, and agricultural facilities thanks to its durability and water-resistance. However, it’s likely a costly and over engineered product for your commercial or agricultural application.

Luckily, there’s an alternative on the market that’s high-strength, 100% waterproof, antimicrobial, and doesn’t require backing material, messy glue, or skilled laborers to install — it’s Trusscore Wall&CeilingBoard.

DISCLAIMER: This video is for demonstration purposes only. Trusscore products are not designed or intended to be used as shown.

What is Trusscore Wall&CeilingBoard?

Trusscore Wall&CeilingBoard are interlocking wall and ceiling panels that are lightweight, low maintenance, and designed to last a lifetime.

Panels are made entirely from polyvinyl chloride (PVC), which is known for its mechanical strength, abrasion resistance, water resistant, and lightweight properties

- Trusscore Wall&CeilingBoard panels are available in 8', 10', 12', 14', 16', and 20' lengths, with custom lengths available upon request.

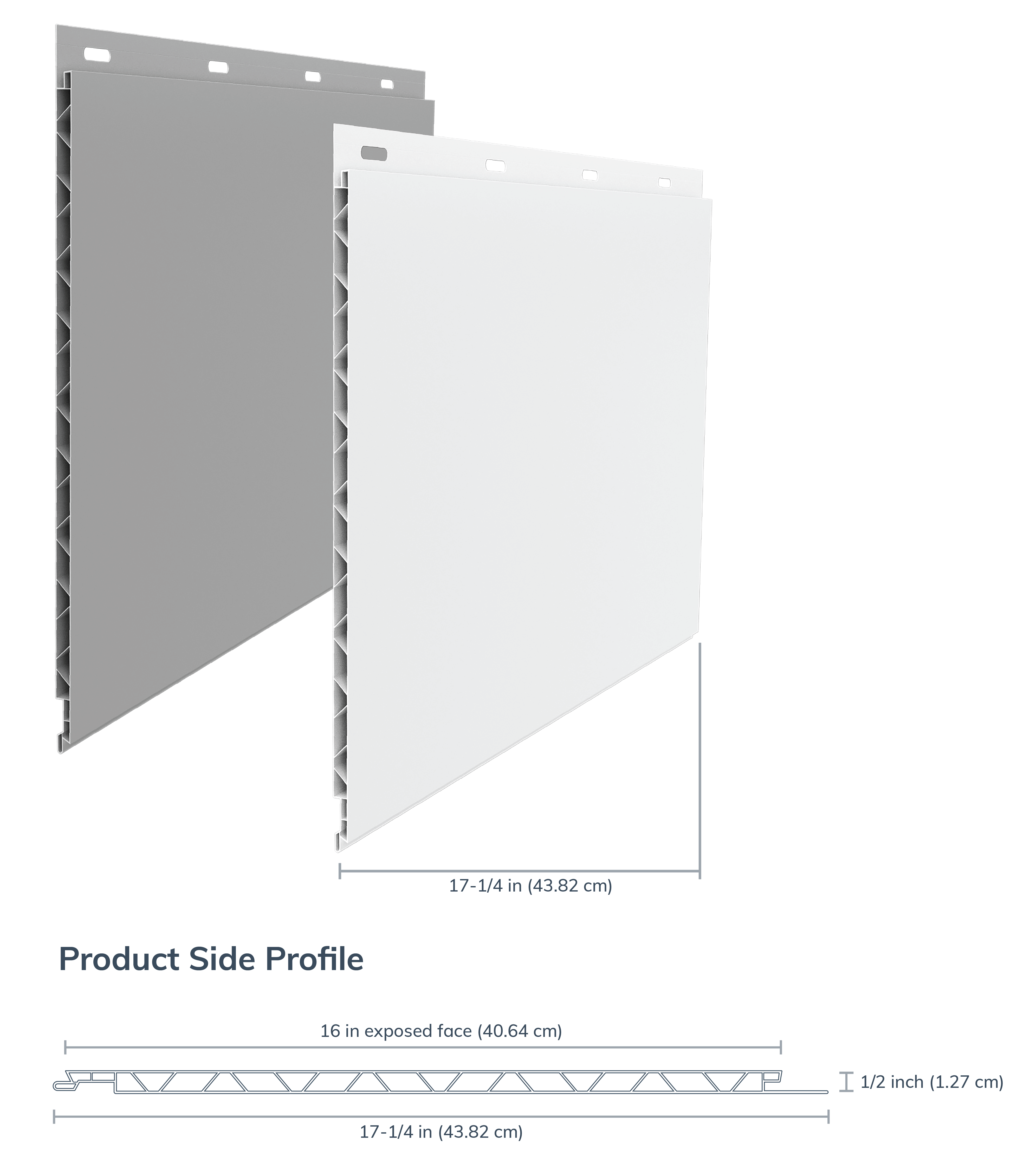

- All panels are 16" wide, ½” thick, and have a unique inner truss design for high-strength and rigidity.

- Panels are pre-finished, non-porous, and have a pre-punched screw flange and tongue and groove interlocking system to hide fasteners for a seamless finish.

- And panels can be installed directly to studs or on top of drywall with no backer material or glue required.

How Does Trusscore Wall&CeilingBoard Stack Up Against FRP?

It’s helpful to think about Trusscore Wall&CeilingBoard versus FRP like the evolution of pressure-treated wood to composite decking.

For a long time, pressure-treated wood was the standard for building decks. It was a familiar product that performed well enough, but builders had to sacrifice on performance and longevity.

At first, there was resistance to trying a new product, but composite decking proved to be stronger, easier to install, more water resistant, and lasted longer than pressure-treated wood. Now, composite decking is the standard for builders who prioritize performance and longevity over everything else. Trusscore Wall&CeilingBoard is transforming the way we build interior walls and ceilings, offering high-performance and so much more!

Let’s compare Trusscore Wall&CeilingBoard and FRP head-to-head. For starters, there are several performance similarities between the two products:

Strength & Durability

FRP was originally designed for the aerospace, automotive, and marine industries, which required a special level of strength from their wall panels. For most commercial projects, FRP is over engineered, and PVC panels will meet and exceed your project’s strength and durability needs. The mechanical strength of PVC combined with the unique truss design of Trusscore Wall&CeilingBoard means that the panels can outlive the buildings they’re installed in. The abrasion resistance of PVC also means that the panels are impact-resistant and can stand up to contact in high traffic areas without showing dents, cracks, or damage.

Cleanability

FRP can be cleaned with soap and water, disinfectants, and can be repeatedly pressure washed. However, stronger cleaners can damage the panels. Trusscore Wall&CeilingBoard panels have a smooth, non-porous surface that can be repeatedly cleaned, pressure washed, disinfected, and sanitized without ever showing signs of damage or wear and tear. Plus, Trusscore Wall&CeilingBoard panels are antimicrobial and provide complete protection against the growth of mold, bacteria, and viruses per third party testing (ISO 846:2019).

Light Reflectivity

White FRP panels are reflective, with manufacturers reporting a light reflectivity value between 0.70 and 0.89. However, the value can vary significantly and some FRP manufacturers don’t report a reflectivity value at all. White Trusscore products have a light reflectivity value of 0.90, meaning they reflect 90% of the light that hits them. This helps you maximize any available natural and fixture lighting in your space, reducing overall lighting costs and boosting your facility’s energy efficiency.

Regulatory Compliance

Many FRP manufacturers are compliant with some combination of the Canadian Food Inspection Agency (CFIA), the Food and Drug Administration (FDA), and the U.S. Department of Agriculture (USDA), if not all three. Trusscore Wall&CeilingBoard is compliant with the CFIA, FDA, and USDA for use in food processing facilities and commercial agricultural facilities. Trusscore Wall&CeilingBoard also meets Current Good Manufacturing Practice (cGMP) facility requirements.

However, Trusscore Wall&CeilingBoard outperforms FRP across several key performance categories, including:

Ease of Install

FRP is difficult to handle, difficult to cut, and requires a multi-step installation process — including the use of backer messy glue — that calls for multiple skilled installers. Trusscore Wall&CeilingBoard doesn’t require backers or glue to install. The pre-finished panels come ready to install, with just a few screws and common tools required.

Installed Cost

FRP often takes multiple skilled laborers hours or days to install. Since Trusscore requires no special tools or skills to install, the pre-finished panels can be installed twice as fast with only one person needed for the job. Factor in material and labor, and Trusscore Wall&CeilingBoard offers a 33% lower installed cost compared to FRP.

Moisture & Water Resistance

FRP is said to be moisture and water resistant, but the panel seams are penetrable. Over time, moisture can cause the plastic to separate from its substrate, creating a space for mold and mildew to grow. Trusscore Wall&CeilingBoard panels are 100% water and moisture resistant, and the presence of PVC means the panels will shed water.

Indoor Environmental Quality

FRP requires glue to install, and the glue is a known source of volatile organic compounds (VOCs) that can jeopardize indoor air quality. Trusscore Wall&CeilingBoard is low-VOC compliant, including low formaldehyde, meaning it ensures a healthy space for occupants.

Sustainability

FRP isn’t easy to recycle thanks to the backing material and glue used during installation, and it may need to be replaced as often as every five years in applications like commercial kitchens. Trusscore has a service life of up to 100 years, is 100% recyclable, and can be recycled up to seven times to make new PVC-based products.

Fire Performance

FRP has a range of fire ratings from Class C to Class A, with most panels generally featuring a Class C fire rating. Trusscore Wall&CeilingBoard has a Class A fire rating — the highest possible rating — with a flame spread index of 10 and smoke developed index of 380 per ASTM E84.

Where Can You Install Trusscore Wall&CeilingBoard?

Trusscore Wall&CeilingBoard is designed to replace FRP in commercial spaces where durability, moisture resistance, and cleanability are among your top concerns, including:

Product Specifications

|

Product dimensions |

TrusscoreWall&CeilingBoard is available in a standard width of 16” and a standard length of 8', 10', 12', 14', 16’ or 20’. Custom lengths are available subject to minimum order requirements. |

|

Durability |

Trusscore Wall&CeilingBoard durability testing results are as follows:

|

|

Volatile organic compounds |

Trusscore panels are low VOC compliant per the California Department of Public Health Standard Method v1.2 testing standard. |

|

Light reflectivity |

White Trusscore panels have a high light reflectivity (LR) score of 0.9, meaning 90% of light will be reflected when it hits our panels. |

|

Antimicrobial testing |

Per third party testing (ISO 846:2019), Trusscore Wall&CeilingBoard provides complete protection against mold and bacteria. |

|

Fire performance |

Trusscore Wall&CeilingBoard has a "Class A" fire rating with a flame spread index of 10 and smoke developed index of 380, per CAN/ULC S102 and ASTM E84 testing. |

|

Recyclability |

Trusscore products are 100% recyclable and can be reground and reused to make new materials. |

Earn LEED certification credits with Trusscore Wall&CeilingBoard

Leadership in Energy and Environmental Design — also known as LEED — is a globally recognized accreditation in the building sector which encourages green, sustainable building design. All Trusscore products, including Trusscore Wall&CeilingBoard can help builders earn credits in the Materials and Resources and Indoor Environmental Quality categories.

Visit our Trusscore & LEED Certification page to learn more.

Download CAD Drawings, Product Specifications, and Technical Information about Trusscore Wall&CeilingBoard

Trusscore offers a library of CAD drawings, product specifications, and technical resources to help architects and designers to streamline your design process and bring your visions to life.

Explore Drawings & Specifications

Want more detailed technical information about Trusscore Wall&CeilingBoard? Explore the resources below.

-

Trusscore Car & Truck Washes Application Sheet

This sheet describes the use of Trusscore products in car and truck wash facilities, including self-service wash bays, automatic conveyor tunnel washes, touchless automatic washes, and commercial truck wash bays. (735.68 KB PDF) - *

-

Trusscore Residential Application Sheet

This sheet explains why Trusscore Wall&CeilingBoard and Trusscore SlatWall are ideal alternatives to drywall and MDF slatwall in residential spaces. (1.20 MB PDF) - *

-

Trusscore Dairy Application Sheet

This sheet outlines the use of Trusscore products in dairy production facilities, including parlor and robot rooms, milk and tank rooms, holding pens, observation rooms, creameries, and more. (1.57 MB PDF) - *

-

Trusscore Pork Application Sheet

This sheet outlines the use of Trusscore products in pork production facilities, including farrowing, nursery, and finishing buildings. (2.44 MB PDF) - *

-

Trusscore Poultry Application Sheet

This sheet outlines the use of Trusscore products in poultry production facilities like layers, broilers, breeders, and pullets. (898.22 KB PDF)

-

Trusscore Cold Weather Installation Technical Guide

This technical installation guide outlines the special adjustments you need to make if you’re installing Trusscore Wall&CeilingBoard in temperatures below 10°C (50°F). (190.92 KB PDF) - *

-

Trusscore Cleaning & Disinfecting Guidelines

This guide provides step-by-step instructions for cleaning, pressure washing, and disinfecting Trusscore products. (148.31 KB PDF) - *

-

Trusscore Wall&CeilingBoard Painting Guidelines

This guide provides product recommendations and tips for painting pre-finished Trusscore Wall&CeilingBoard panels. (114.65 KB PDF) - *

-

Trusscore & Epoxy Floors Technical Guide

This guide provides installation recommendations when installing Trusscore products in applications where epoxy flooring is also used. (415.48 KB PDF) - *

-

Trusscore Wall&CeilingBoard Backloading Guidelines

This technical guide helps determine panel deflection when installing Trusscore Wall&CeilingBoard on ceiling joist spans with different insulation types and R-values. (108.96 KB PDF)

-

Trusscore Wall&CeilingBoard Fire Resistance Test Report – USA

This report details how Trusscore Wall&CeilingBoard meets the ASTM E84-18 criteria for surface burning characteristics. (1.17 MB PDF) - *

-

Trusscore Wall&CeilingBoard Fire Resistance Test Report – Canada

This report details how Trusscore Wall&CeilingBoard meets the CAN/ULC S102.2-18 criteria for surface burning characteristics. (1.03 MB PDF) - *

-

Trusscore Wall&CeilingBoard Fungi Resistance Report – USA

This report details the performance of Trusscore Wall&CeilingBoard against fungal growth per ASTM G21 standards. (432.77 KB PDF)

-

Trusscore Wall&CeilingBoard Warranty

This document details the 20-year standard warranty and limited lifetime extended warranty of Trusscore Wall&CeilingBoard. (79.11 KB PDF)