Customer Story

A Kitchen Even Your Mother Would Love

The Rundown

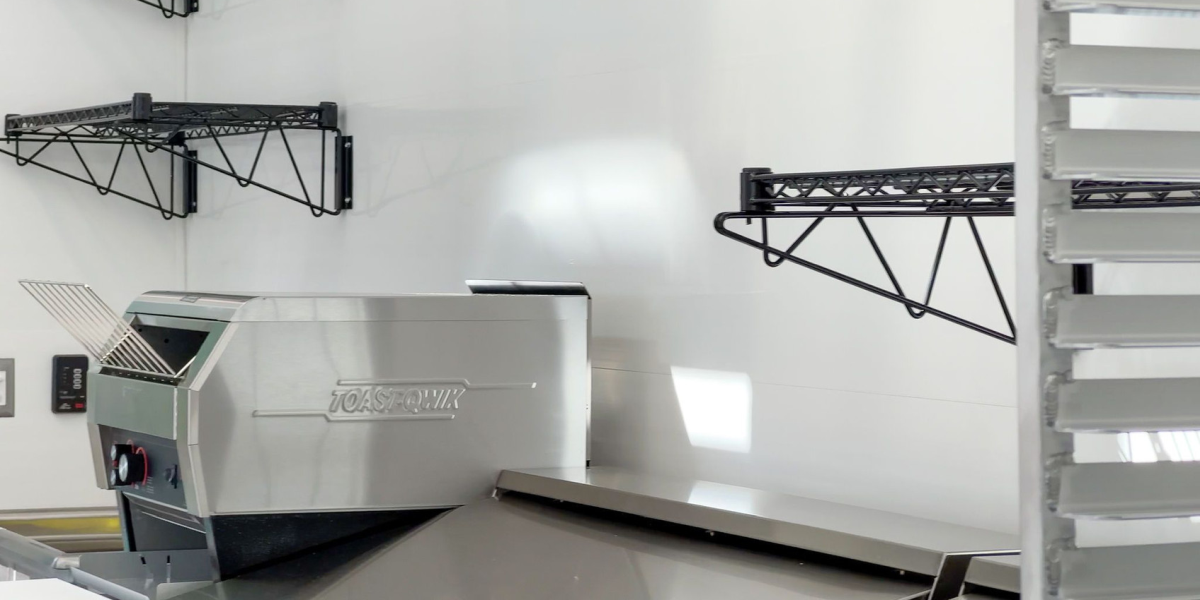

A 190-square-foot mobile kitchen that serves as a stopgap and sales opportunity for a growing bagel deli, Call Your Mother Deli, as they open new brick-and-mortar stores across the country. The kitchen was designed by tiny home contractor Movable Roots, and Trusscore Wall&CeilingBoard is installed throughout the entire kitchen from floor to ceiling.

Call Your Mother Deli Mobile Kitchen

- Location: Melbourne, Florida, U.S.A.

- Application: Commercial Kitchen

- Product(s): Trusscore Wall&CeilingBoard

- Installer: Movable Roots

About Call Your Mother Deli

Call Your Mother Deli started as a neighborhood bagel shop in Washington, D.C. in 2018. Since then, it’s opened eight more stores in the D.C. and Maryland area, with three new storefronts set to open in Colorado in 2023.

About Movable Roots

Movable Roots is a tiny home builder based in Melbourne, Florida. The company was founded in 2016 when Mike Cheatham, Vice President of Movable Roots, was looking to build a tiny home but wasn’t happy with what was available on the market.

The Goal: To Create a Food Truck that Fills in the Gaps for Brick-and-Mortar Stores

As Call Your Mother Deli grew into new markets, they knew they would have to find a way to serve customers while their new brick-and-mortar locations were in the works.

“Call Your Mother Deli is an established brand up in the D.C. area already, and they had brick and mortar stores,” explains Alex Cheatham, Production Director at Movable Roots. “They were looking for a solution for when they're building their new storefronts — their new brick and mortars — to start generating marketing sales. ‘How can we start producing food for customers when our brick and mortar isn't finished yet?’”

That's when they found Movable Roots.

“We needed to build an off-site, on-wheels mobile kitchen that they're able to set up in front of some of their new storefronts as they're under construction. And that space needed to fit their needs until they have their full-sized kitchen,” says Alex.

The Challenge: Traditional Materials like FRP are Too Heavy and Ugly for Mobile Kitchens

Creating the perfect mobile kitchen presents challenges: Building materials must be waterproof, easy to clean, and light in weight. While fiber reinforced plastic (FRP) checks the first two boxes, it presents a big problem.

“FRP is really a go-to in what I've had experience with in some of the early market of the commercial kitchen space. But a big factor that we have to take into account in everything that we do is weight. With FRP, you have to put up a heavy backerboard for the FRP to go against. And to be honest, FRP is not very aesthetically pleasing.”

Plus, mobile kitchens can be seen by customers as they place their order, the material you choose to build with needs to look as good as it performs.

“Most of the time, the kitchen is never seen when you go to a restaurant. You never see the kitchen. But in a unit like this, the orders are happening at the kitchen window. And just eight feet behind [the window] is all of the walls that the customer can see. So, the wall finish we chose wasn't just for the employees. It's also for everyone who walks up to that truck, and they can see in. You can't hide. It has to be a good finish,” says Alex.

“As a result, we were looking for [a product] that aesthetically gave us the look we wanted while still giving the customer the ability to completely wash the place down and wipe it down super easily,” adds Mike.

The Result: Trusscore Creates a Luxurious Finish that Meets Call Your Mother Deli’s Unique Needs

Enter Trusscore Wall&CeilingBoard. Made from PVC, Trusscore Wall&CeilingBoard is a lightweight, interlocking wall and ceiling system that’s an alternative to FRP in commercial kitchens of all shapes and sizes. Why?

- Trusscore Wall&CeilingBoard panels are 100% water resistant and moisture resistant, so steam and humidity from cooking and water from cleaning are never a problem.

- The non-porous surface of Trusscore is easy to clean — you can easily wipe down panels with soap and water or with chemical cleaners. Plus, the panels are stain resistant, so they’ll always look as good as the day they were installed.

- Panels are fully compliant with requirements set out by the Canadian Food Inspection Agency (CFIA), Food and Drug Administration (FDA), and U.S. Department of Agriculture (USDA) for areas where food is prepared.

- Pre-finished panels have a tongue and groove interlocking system designed to hide all fasteners for a seamless finish.

- Panels are available in a variety of lengths — 8', 10’, 12’, 14’, 16’, and 20’ — and are ½" thick for added durability. Custom lengths are also available upon request.

- And Trusscore offers a full range of framing, finishing, and specialty trims that are easy to install and put the perfect touch on any project.

For a contractor like Movable Roots, the last two points are especially important.

“The nice thing about Trusscore was that we could order it in so many different lengths, and you can even special order it in other lengths. That really was another key factor,” says Mike.

“[The variety of lengths] helped us eliminate almost all seams. Trusscore very much let us minimize the seams and minimize the trim with [the H-Channel Snap-In Kit]. I heard nothing but positive things from our crew on being able to install it and have it work for us,” adds Alex.

But the water resistance and cleanability of the product was important, too.

“From a builder standpoint, there's cleanability for the end user, but also for us working with it,” says Alex. “Sometimes stuff happens, and things might get a ding or a dent of scratch from us in the build process. [Trusscore] withstood the amount of time it took for us to put the unit together, moving in all the heavy equipment. It was very easy for us to clean as well before finishing up.”

“Any place where you want to keep a very clean, washable, waterproof setting, it would be my go-to product,” adds Mike.

Why Does Movable Roots Choose Trusscore Over Its Competitors?

When building the units, Movable Roots was first introduced to a competitive PVC panel manufacturer, and the contractor experienced hiccups from buying the product through installing it. Here’s why Movable Roots made the switch to Trusscore Wall&CeilingBoard:

Local Availability

“I was upset because when I ordered [the competitive product], I had to order it out of California. And, the very next week, I go into our local building supply place where we do our cabinets, and there's this whole Trusscore display and signage for Trusscore products there. When I did some more research online, I realized that the Trusscore product is a superior product, and it was nice to be able to get it from one of our local suppliers,” explains Mike. “We like to avoid having to buy materials through a third party. We liked the fact that we could go right to our distributor, Dixie-Ply, and get the product. For a lot of the other products, we have to go to whoever Dixie-Ply supplies or different things like that. For the products we used, they basically gave us a list of what they had in stock and could turn around quickly. We fit our takeoff off that list.”

Superior Performance

“The tongue and groove [interlocking system] on the Trusscore was slightly different [than a competitor product we previously used] and we liked that,” says Mike. “And the very clean, smooth finished look [we achieved] by using the Trusscore trim pieces, including the Outside Corner trim, the Inside Cove Corner trim, the H Channel Snap-In Kit trim, and using everything together really just helped our end product look amazing. And I think that's one of the things that, when it's all said and done and we have people come into the unit, how clean it looks aligns with what we try to do with the tiny homes on wheels. We try to give [each unit] that elevated kind of look and appeal.”

-

Installation Flexibility

“One issue I had with [the competitor], was they only show all their panels being installed vertically. They eventually told through email that I could install it horizontally. But [Trusscore] is advertised as being horizontally or vertically installed. I didn't have to chase down Trusscore installers to say, ‘Hey, are you sure I can put this horizontally?’ Because vertically with our stud placement, especially if you're using the product in new construction, you're not going against the substrate, so everything needs to be horizontal,” says Mike.