Ever since humankind moved out of caves and erected shelter, there’s been a need for walls and wall coverings. We trace the evolution of wall solutions, right up to the present day.

Walls of progress

- Wall materials have a long and storied history, one that traces the evolution of humankind

- From mud to gypsum, from lathe and plaster to drywall, the development of wall coverings has mirrored changes in technology

- Today, drywall, the wall covering of choice, is being challenged by better performing and more technologically capable materials

The walls in a home don’t normally command a lot of attention, unless it’s time to repaint or remodel.

But walls, and the materials that cover them, have a long history, one that’s as old as civilization itself.

And it all started – at least, it’s believed to have started – with mud.

There is evidence of mud plaster technique dating back to the 8th millennium BC in the Fertile Crescent, or the geographical area that is known today as the modern-day Middle East. Mud, sometimes mixed with sand, straw and clay, could be spread over a wooden or straw scaffolding and it would harden into a smoothish surface, one that was relatively durable and helped keep out the elements.

Advance forward a few millennia to ancient Egypt, and there’s evidence of use of a gypsum-based plaster technique in the pyramids of Giza. The composition of the Egyptians’ gypsum plaster, according to the e-magazine Walls&Ceilings, was amazingly advanced, and of a superior quality to that used even today, suggesting the material had been used for generations and refined along the way.

Gypsum endured

Gypsum plastering techniques were further refined by the ancient Greeks, and then the Romans.

And gypsum endured. The product proved to be long lasting. There’s evidence of its use for exterior and interior decorative purposes through the Mediaeval period.

Over time, the gypsum-based plastering process became known as “wattle and daub.” A “wattle,” namely a subsurface scaffolding or matrix made from straw or wood, was used to support a “daub,” a wet mud or gypsum mix that was spread overtop the wattle and left to harden.

By the mid 17th century, as industrial and woodworking processes evolved, small wooden strips, known as lathe, became the product of choice for the underlying

substructure. The lathe was then covered with a wet, gypsum-based plaster coating. As metal working processes improved during the industrial revolution, a metal lathe was often used instead of wood.

The technique proved its use, and plastering evolved into a skilled trade. But plastering the walls in a house was slow. And it was difficult to get plaster to dry in cold temperatures. By the mid-1940s, with wartime and post-war housing in huge demand, drywall emerged as a way to speed and simplify construction.

Other wall products have been experimented with since, such as concrete tiles, metal sheets and wood paneling. In fact, where the latter goes, thin wood panels were immensely popular during the 1970s and early 1980s and became the product of choice for any basement renovation.

Drywall’s limitations

Today, it’s drywall that is ubiquitous, but drywall comes with limitations. It performs poorly in wet conditions. Sheets of drywall are heavy. The process of installing drywall is slow and messy, requiring several steps. And it’s not very durable – the slightest contact with furniture can produce a dent or hole.

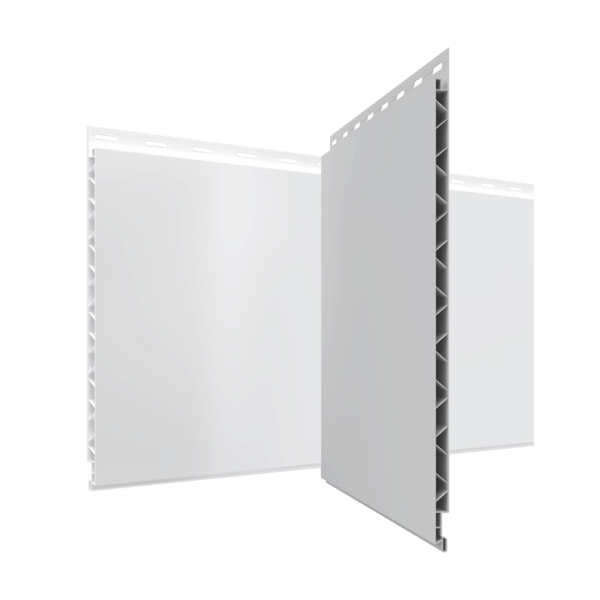

New, better performing, wall products are emerging, including PVC panels like Trusscore Wall&CeilingBoard. The advantages of PVC panels are that they’re lightweight, fast to install, and they’re incredibly strong and durable, typically outlasting the buildings within which they’re installed. Trusscore Wall&CeilingBoard sheds water and, unlike drywall, won’t swell or degrade when it gets wet.

Wall materials will continue to evolve, and as they do they’ll leave a legacy of human progress. The writing is, well, on the wall.

Products for Interiors

Wall&CeilingBoard

Trusscore Wall&CeilingBoard is an interlocking, interior PVC wall and ceiling panel that is lightweight, low maintenance, and outperforms alternative products like drywall and FRP.

Learn More