This post was originally published in January 2022. Last updated: February 2024.

PVC, or polyvinyl chloride, is more than just a mouthful of letters – it's a versatile, durable, and widely used building material that has found its way into countless homes.

From plumbing to flooring and roofing to wall panels, PVC's adaptability makes it a homeowner's best friend. In this blog post, we'll delve into 15 frequently asked questions about PVC, shedding light on its properties, applications, and considerations.

1. What is PVC?

PVC stands for polyvinyl chloride, which is a thermoplastic synthetic polymer. PVC is a versatile material known for its durability, strength, and resistance to abrasion, chemicals, weather, and fire. It’s commonly used in pipes, fittings, window frames, flooring, cables, and wall and ceiling panels like Trusscore Wall&CeilingBoard, Trusscore SlatWall, NorLock by Trusscore, and RibCore by Trusscore.

2. How is PVC manufactured?

PVC manufacturing is a three-stage process:

- Chlorine and ethylene are combined to form a compound called ethylene dichloride.

- Ethylene dichloride is heated at an extremely high temperature in an environment with no oxygen (a process called pyrolysis) to form the vinyl chloride monomer.

- The vinyl chloride monomer is chemically altered in a multi-stage process called polymerization to create PVC polymer resin.

In the case of Trusscore, this resin is heated and pushed through proprietary dies in a process called extrusion, resulting in Trusscore products.

3. What are the different types of PVC?

There are two types of PVC: rigid and flexible. Rigid PVC is used to make various construction products like plumber’s pipe, electrical conduit, window frames, doors, and wall and ceiling panels like Trusscore Wall&CeilingBoard.

Flexible PVC has plasticizer added, which makes it softer and more malleable. It’s used to make a variety of products, including cable insulation and flooring.

4. What are the properties of PVC?

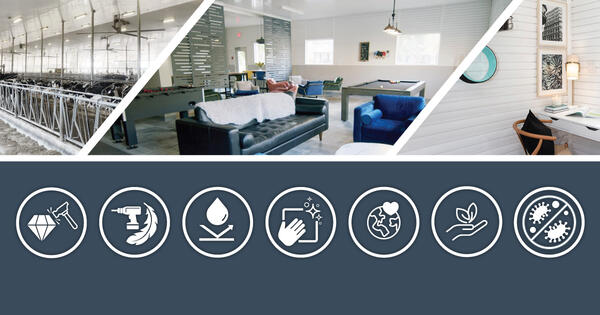

PVC is known to be durable, lightweight, versatile, recyclable, and resistant to abrasion, water, chemicals, weather, and fire. In the context of wall and ceiling panels like Trusscore Wall&CeilingBoard, here’s how you benefit from PVC’s properties:

Strength and durability: PVC combined with a unique inner truss design makes Trusscore panels long-lasting and resistant to impact, dents, and cracks.

Lightweight and ease of installation: Pre-finished Trusscore panels are 40% lighter than drywall and install four times faster with no need for mudding, taping, priming, or painting.

Moisture and water resistance: Trusscore panels are completely water-resistant, preventing degradation even in wet environments.

Cleanability: Trusscore panels are easy to clean with a simple wipe and can withstand detergent or pressure washing.

Hygienic: Trusscore panels are antimicrobial and resist bacteria, mold, and fungus growth (per ISO 846:2019), meeting hygiene standards for various industries

Indoor environmental quality (IEQ): Trusscore panels enhance indoor air quality, lighting, and comfort, meeting safety standards for occupants.

Environmental sustainability: Trusscore panels are 100% recyclable and can be reused to reduce waste.

5. What are the main uses of PVC?

The primary uses of PVC include:

- Construction: PVC is widely used in the construction industry for pipes, fittings, window frames, siding, roofing membranes, flooring, insulation materials, and wall and ceiling panels.

- Agriculture: PVC is used in agriculture for irrigation pipes, greenhouse films, and agricultural fencing due to its resistance to chemicals and weather.

- Automotive: PVC is used in automotive interiors for upholstery, dashboard components, door panels, and wiring insulation due to its durability and resistance to chemicals and weather.

- Electronics: PVC is used in cable insulation and sheathing for electrical wires and cables due to its electrical insulation properties.

- Packaging: PVC is used in packaging materials such as shrink wrap, cling film, and blister packs due to its transparency and barrier properties.

- Consumer Goods: PVC is used in various consumer goods such as toys, kitchen utensils, bottles, and credit cards due to its versatility and low cost.

- Healthcare: PVC is utilized in medical devices such as IV tubing, blood bags, catheters, and medical packaging due to its biocompatibility and sterilizability.

- Signage and Graphics: PVC is used in signage and graphics applications such as banners, posters, and display boards due to its lightweight nature, durability, and printability.

These are some of the main applications of PVC, but its versatility allows for a wide range of uses across different industries.

6. How does PVC compare to other materials like wood, metal, or other plastics?

PVC has several distinct characteristics that set it apart from other materials like wood, metal, and other plastics:

- Durability: PVC is highly durable and resistant to rot, corrosion, and pests, making it suitable for outdoor applications where wood may degrade and metal may rust.

- Versatility: PVC is a versatile material that can be molded or extruded into various shapes and sizes, making it adaptable to various applications.

- Low Maintenance: PVC requires minimal maintenance compared to wood and metal, as it does not need to be painted, stained, or sealed regularly.

- Cost: PVC is often more cost-effective than wood and metal, especially in the long run, due to its durability and low maintenance requirements.

- Weight: PVC is lightweight compared to metal, making it easier to transport and install in specific applications.

- Insulation: PVC offers good thermal and electrical insulation properties, making it suitable for applications where insulation is important, such as electrical wiring and piping systems.

- Environmental Impact: PVC production can have environmental impacts due to the use of chlorine and additives, but it can also be recycled, unlike some other plastics.

7. Is PVC waterproof?

Yes, PVC is waterproof. PVC is naturally resistant to water and doesn’t absorb moisture, making it ideally suited for applications where waterproofing is necessary, like pipes, window frames, roofing membranes, and wall panels. Trusscore Wall&CeilingBoard has an interlocking tongue-and-groove system that means panels install with a watertight seal, so you never have to worry about water getting behind the waterproof panels, either.

8. Is PVC safe for food contact?

Flexible PVC products contain additives like plasticizers, which can be harmful to human health. Rigid PVC products like Trusscore Wall&CeilingBoard do not use plasticizers and are a safe choice for applications where panels come into direct contact with food and water.

9. Is PVC recyclable?

Yes, PVC is recyclable. PVC products like Trusscore Wall&CeilingBoard are 100% recyclable and can be recycled up to six or seven times to create new PVC products.

10. How long does PVC last?

PVC is extremely durable and long-lasting, but its lifecycle estimate depends on its use case. PVC products can last between 50 to 80 years outdoors and 100 years or more indoors. Plus, since PVC lasts a long time, it doesn’t need to be replaced as frequently as other products, which is good for the environment.

Life-cycle estimates vary depending on the use case. Best guesses on longevity range from 50 to 80 years outdoors and 100 years or more indoors. Because PVC lasts a long time, it doesn’t need to be replaced as frequently as other products, which is good for the environment.

11. Is PVC UV resistant?

The UV resistance of PVC depends on the type of PVC, the chemical makeup of a PVC product, and whether it’s intended to be used indoors or outdoors. Over time, UV radiation from sunlight will cause most PVC products to fade in color. Trusscore PVC products contain an additive that prevents UV damage so the panels will never yellow or fade.

12. What are the fire safety properties of PVC?

PVC exhibits fire retardancy, low flammability, self-extinguishing behavior, reduced smoke emission, and minimal toxic gas release when burned. In simpler terms, PVC doesn't catch fire easily, and if it does, it tends to stop burning quickly, produce less smoke, and emit fewer harmful gases, which helps keep people safer in case of a fire. Made from PVC, Trusscore Wall&CeilingBoard has a "Class A" fire rating — the best available — with a flame spread index of 10 and smoke developed index of 380.

13. How does PVC contribute to energy efficiency in buildings?

PVC contributes to energy efficiency in buildings in several ways:

- Insulation: PVC windows and doors have excellent insulation properties, helping to reduce heat transfer between the interior and exterior of a building. This can lead to lower energy consumption for heating and cooling, thereby improving energy efficiency.

- Sealing: PVC materials can be tightly sealed to prevent air leaks and drafts, improving the overall thermal performance of a building and reducing the need for additional heating or cooling.

- Daylighting: PVC window frames can be designed to maximize natural daylight penetration into a building, reducing the need for artificial lighting during the day and decreasing energy usage.

- Durability: PVC building materials are durable and long-lasting, requiring minimal maintenance over their lifespan. This reduces the need for frequent replacements and associated energy expenditures for manufacturing and transportation of new materials.

- Reflectivity: Some PVC roofing and wall cladding materials have high light reflectivity, which can help reduce heat absorption and lower cooling loads in buildings, particularly in warm climates. Trusscore Wall&CeilingBoard has a light reflectivity value of 0.9 0 — this means 90% of the light that strikes the surface of our panels will be reflected. The reflectivity of Trusscore panels helps maximize all natural and fixture lighting in a room to keep costs low and save on energy consumption.

- Recyclability: PVC materials can be recycled, allowing for the reuse of resources and reducing the energy consumption and environmental impacts associated with the production of new materials.

Overall, PVC contributes to energy efficiency in buildings by improving insulation, reducing air infiltration, maximizing daylighting, and providing durable, recyclable building materials that require minimal maintenance over their lifecycle.

14. Can PVC be painted?

Yes, you can paint PVC. The key to painting PVC is to use the correct type of primer and paint, so always check with a product manufacturer for recommendations. For Trusscore products, we recommend using 100% acrylic latex paint or acrylic latex paint with urethane additive to paint Trusscore panels. We also recommend using self-priming paints or primer and paint combination products where possible. For more information and product recommendations, check out our Painting Guidelines.

15. How do you clean PVC products?

Trusscore PVC products have a smooth, non-porous surface that can easily be wiped down, pressure washed, or disinfected.

For day-to-day cleaning, we recommend washing the panels using a sponge or soft cloth and a mild cleaning solution. If dirt is difficult to remove, we recommend cleaning the walls using a solution that contains 1/3 cup of laundry detergent (e.g., Tide®), 2/3 cup of tri-sodium phosphate (e.g., TSP®), and 3.79 liters (or 1 gallon) of water.

If hand washing doesn't get the job done, try pressure washing. To safely pressure wash Trusscore products, we recommend:

- Using a small- to mid-size power washer with less than 3,000 psi

- Using a wide spray nozzle angle (40° or greater is preferred) to distribute the water pressure across the wall

- Keeping the power washing nozzle at least 4 to 6 feet away from the wall at all times

For more information on how to properly clean and disinfect Trusscore products, download our Cleaning & Disinfecting guidelines document.

Have more questions about PVC or Trusscore products that weren’t covered in this blog post? Check out the Trusscore FAQ.

![6 Best Drywall Alternatives for Garage Walls [2026 Cost & Install Guide]](/content/images/cache/blog/best-alternatives-to-drywall-for-garage-walls-refresh/best-alternatives-to-drywall-for-garage-walls-refresh-social.45933b7d.jpg)