Customer Story

Trusscore Empowers Hydroponic Innovation

The Rundown

A 336-square-foot standalone indoor grow room for running trials of microbial inoculants on hydroponic systems growing lettuce plants. Trusscore Wall&CeilingBoard is installed on the walls and ceiling.

About Ceragen

- Ceragen creates microbial inoculants for the hydroponic fruit and vegetable industry. The microbial inoculants – most easily thought of as probiotics for plants – are added to hydroponic systems and are designed to increase crop yields and reduce plant stress.

- With a microbial inoculant for tomatoes and lettuce already on the market, Ceragen is currently researching and developing microbes for a second lettuce product, a cucumber product, a strawberry product, and more.

“It’s beneficial bacteria that go into the roots of the plants, generally through the watering system, latch onto the roots, and help the plant uptake nutrients and regulate things like heat stress better,” says Matthew Rose, Co-founder and Chief Technology Officer of Ceragen. “We see, on average, a 10 to 20% yield increase from the use of our product that’s put in the grower’s existing hydroponic system.”

The Goal: To Create Durable, Moisture Resistant Indoor Grow Rooms for Lengthy Plant Trials

Inside their new downtown space, Ceragen is running controlled trials to test new microbial formulations on different fruits and vegetables. As part of the process, they’ve created a 12 by 28 foot grow room for a lettuce trial.

“We have currently 650 lettuce plants growing right now,” says Matthew. “Every single one of these systems is as replicated as possible, and we test out different microbial inoculum formulations in the various ones. We’ve got the controls to compare against the inoculate and to see which ones are growing larger lettuce plants.”

And Ceragen’s experiments don’t stop with lettuce plants.

“We’re mocking up what a cucumber setup will look like. [Cucumbers require a trial of] about three or four months. And we’ll just keep going up from there. Strawberries are six months, peppers are 12 months again. If that goes according to plan, we’ll build actual rooms that are kind of [the same scale as the current room], and there will be four [indoor grow rooms] in here.”

The Challenge: Ceragen Grow Rooms are Hot and Humid Spaces that are Highly Conducive to Mold Growth

“What we're trying to do is mimic what people are seeing in the greenhouse as much as possible. We've been working with some growers down in Texas, and the air temperature in their greenhouses can be anywhere upward of 35 degrees Celsius during the day. [In our grow room], we're getting up to 30 degrees when the lights are all on and we don't have heating in here.”

In addition to high temperatures, humidity is a factor, too.

“It gets quite humid in here. Typically, it’s hovering around the 75 to 80% range. We don’t have any dehumidification in here, either. [Without Trusscore], I think we would have created a regular, drywalled room and lined the walls with [a reflective Mylar] material. It provides some reflectivity, and it provides some insulation.”

But these materials aren’t water resistant, and the room's humidity can result in mold, jeopardizing the trial and resulting in a total rebuild of your grow room.

“You 100% run the risk of mold growth [with drywall and Mylar]. We’ve seen other growers take plastic tarping, put that down, and then put the reflective stuff over top of that. It’s a multi-step process, and it's not great because you have just taped down tarps as your vapor barrier. It’s not a good solution. Plastic paneling is definitely the way to go.”

The Result: Trusscore Wall&CeilingBoard Creates Easy to Clean Grow Rooms that Withstand Constant Moisture

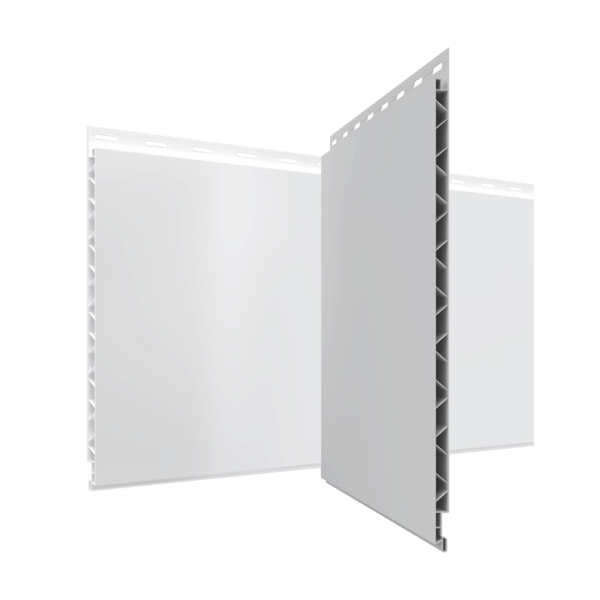

For Ceragen, Trusscore Wall&CeilingBoard was the answer. Made from PVC, the interlocking wall and ceiling are an ideal alternative to FRP and plastic tarping in indoor grow rooms of all shapes and sizes for several reasons:

The abrasion resistance of PVC means that Trusscore Wall&CeilingBoard panels are impact-resistant and can stand up to contact without showing dents, cracks, or damage — they’ll never have to be replaced, unlike plastic tarping.

“A bunch of our sustainability is lab-focused, where we're trying to reduce the amount of plastic we use. A little dirty secret of the whole entire biology and chemistry lab industry is that they go through so much plastic, it's terrible,” explains Matthew. “We've been doing a lot of transitioning towards using glassware and instead of throwing it out, just sterilizing it and reusing it. [With Trusscore], we also don’t have to worry about replacing torn plastic tarps.”

Trusscore Wall&CeilingBoard panels weigh 40% less than drywall and can be installed by one person with no special tools or skills required. Panels also have a pre-punched screw flange and a tongue and groove interlocking system, allowing it to be installed four times faster than drywall and twice as fast as FRP.

“We installed [the panels] ourselves, and it was great. The way the Trusscore slots together was really great,” says Matthew. “The electrician mounted all the wiring. So as far as like sentiment towards ‘Are you able to install electrical on it?’ It’s totally good. He had no troubles installing electrical on the ceiling.”

Matt Rose, Ceragen, Co-Founder and Chief Technology Officer

Trusscore panels are 100% moisture and water resistant. The presence of PVC means the panels shed water and won’t absorb airborne moisture, so they won’t degrade or deteriorate in wet, damp, or humid environments, and they won't support the growth of mold or mildew.

And Trusscore Wall&CeilingBoard panels have an antimicrobial coating that’s designed to prevent, contain, and destroy bacteria, fungi, and viruses. Per third-party testing (ISO 846:2019), Trusscore Wall&CeilingBoard provides complete protection against mold and bacteria. As a bonus, the non-porous surface of Trusscore panels is also easy to clean and disinfect — panels are also easy to clean and disinfect — they can't be harmed by detergent or chemical cleaners and can be repeatedly pressure washed.

“As far as paneling, we’re able to hydrogen peroxide down the entire room. The fact that we can do that means it’s really easy for us to disinfect, and we don’t have to worry about fuming out the entire rest of the space,” says Matthew.

Thanks to these benefits, Trusscore Wall&CeilingBoard has earned Ceragen’s stamp of approval: “[Trusscore] has worked out really well for us; we’re really happy with it. Ten out of ten, would use again.”

Trusscore Has Your Growing Covered

Wall&CeilingBoard

Trusscore Wall&CeilingBoard is an interlocking, interior PVC wall and ceiling panel that is lightweight, low maintenance, and outperforms alternative products like drywall and FRP.

Learn More