There are plenty of dock frame and dock decking options on the market. With thought and planning, you’ll land on a combination of frame and deck that will soon have you singing, “Sittin’ on the dock of the bay ....”

Boat dock design made easy:

- Installing a dock enhances any waterfront property

- Choosing the right style of dock for your waterfront and pairing it with right decking material is the key to a successful dock project

- Trusscore makes a dock decking material called DockDeck by Trusscore that looks smart, has low heat retention, and is designed to handle all that mother nature can dish out

When Otis Redding first sang his 1968 classic “Sittin’ on the dock of the bay,” he omitted any mention of all the thought and planning needed to arrive at a successful dock project.

Waterfront property owners who have had a dock installed, on the other hand, know there’s no getting around some big decisions on design, location, and materials before you’re able to enjoy a dock for summertime lounging. Simply put, there are plenty of options when it comes to boat docks. Each one offers unique advantages depending on the use case and site conditions. The key is to match your needs and location with the available options. Let’s sort them out.

The Use Case

The first step in landing on a suitable residential boat dock design requires answering a fundamental question: what will the dock predominately be used for? The answer will likely govern your dock’s size, structure, materials, and cost. There are plenty of use-case options and combinations, including swimming, diving, entertaining, and boat mooring. In the latter case, the size of the boat – or is it boats, plural? – will play a role in determining suitable size and design. Swimming or entertaining will likely require a wider, more spacious footprint.

Location, Location, Location

Site-specific considerations will also dictate dock design and material choices. The goal here is to arrive at a dock that can perform within the constraints of a particular locale.

Considerations include:

- Water depth and drop off

- Water level changes over time

- Wind and wave impact

- Lake bottom conditions

- Shore geology

Each specific dock type (which we’ll explore below), is designed to perform according to a particular set of environmental conditions. A floating dock, for example, would be too unstable, and therefore a poor choice, in an area subject to high winds and wave action.

Money Matters

The project budget will contribute to dock size and materials. A dock with a larger footprint will, as one would expect, cost more than one that is smaller. Ongoing maintenance and the associated cost of maintenance is another consideration. Again, a larger dock will cost more to maintain than a smaller one. You’ll want to choose materials that will last under the harsh conditions of sun, wind, and water. Be prepared to make compromises according to your available budget; establishing a budget at the outset of your project will help keep costs under control.

The Fine Print

Be sure to do a thorough investigation of the laws and regulations governing dock projects in your jurisdiction. Are docks even allowed on your particular body of water? Are there rules governing certain types of structures? Are permits necessary before a project can begin? And are permits for certain kinds of docks easier to obtain than others? A floating dock, which is completely removable for winter storage and does not make contact with the lake or river bed, may be viewed as having a lower environmental impact than other designs and hence more acceptable in some areas.

If you’re uncertain how to proceed, contact your municipality and if the rules prove difficult to navigate, consider enlisting legal help.

Dock Structure Types

With the preliminaries and preparation behind you, it’s time for some big decisions. There are two broad categories of docks available: permanent and removeable. Within each category there are several options available, all of which come with advantages and disadvantages. Let’s break them down.

Permanent Docks

Permanent docks offer one enormous advantage: less labor each fall and spring because they don’t need to be removed and replaced as the seasons change. Their disadvantage is that in areas with harsh winters and heavy ice build-up, the dock structure can shift or be damaged. And in places where the water level shifts, permanent docks can’t easily be adjusted to suit the level of the water.

There are two types of permanent docks:

- Crib docks are docks which have one or more “crib,” structures which are typically made of wood and provide support for the overall structure, anchoring the structure permanently to the waterbed. Each crib resembles a large crate, with the interior of the crate normally filled with rocks. The advantage of crib docks is they are strong, providing the best strength and structural integrity, useful in places with high wave and wind action. The disadvantage of a crib dock is it's expensive, and in winter it’s possible that the crib structure or supports could be damaged by ice.

- Pier docks or pile docks are docks which are supported by large steel or wooden posts driven into the waterbed by a pile driver. They’re extremely stable and like a crib dock are able to withstand severe weather. Like crib docks, it’s possible that winter ice may damage or shift the piers, and pile docks offer little in the way of adjustability if water levels change.

Removable Docks

Removable docks, as the name would imply, are removed from the water each autumn and replaced in the spring. Their advantage is they aren’t subject to damage from winter and ice and they can be adjusted each season according to water levels or, in the case of a floating dock, will self-adjust. Their disadvantage is that removing and replacing them each season can be cold, difficult work.

There are several types of removable docks:

- Pole docks are built on a frame, usually made of steel, which is used to carry and support the dock decking material. The entire structure is supported in the water by poles placed in the water that extend down to the lakebed or riverbed. Pole docks work best in shallow, non-rocky water that is not deeper than four feet; any deeper and the structure becomes unstable. Pole docks require a firm surface on the bed of the waterway to support the structure and would not be suitable in soft areas where the supporting poles could sink or shift. Removal of pole docks for the winter can be labor intensive.

- Tower docks solve the problem of removal and replacement through the installation of a frame tower – hence the term tower dock – at the shore end of the dock to act as a support for a wire and pully system capable of lifting the dock out of the water and lowering it back the next season.

- Rollings docks have wheels installed at the bottom of the supporting poles. The entire structure can then be wheeled in and out of the water as the owner requires. Wheel docks require a way to lock the wheels firmly in place to keep the structure from shifting during storms or heavy wave action.

- Floating docks are what the name implies – framed structures that support decking material and float on the water’s surface. Some floating docks are anchored to the bed of the body of water upon which they float, much like a boat. Floating dock units can usually be daisy-chained together as needs change to create a more expansive deck area. The advantages of a floating dock is that the layout and footprint can be adjusted easily. If the body of water the dock is intended for is subject to changes in depth from one season to the next or during a season, the dock simply floats to the correct height. The disadvantage of a floating dock is it is less stable than a fixed dock, meaning it is subject to movement from wave action, and even from a person stepping onto the dock’s surface. For some people, the constant movement can be unsettling; if the body of water for which the dock is intended has a lot of boat traffic and/or wave action, a floating dock might not be suitable.

Material Selection for Your Dock Type

Once you’ve chosen your dock type, a decision needs to be made on the type of material you’ll use to create the structure that will support the decking and the material of the decking itself. For the structure, there are three basic options: wood, steel and aluminum.

The advantage of wood is it has an undeniable aesthetic and it’s easy to work with. The disadvantage is that constant exposure to sun, wind and water will cause it to degrade and eventually require replacement, which can become expensive.

Aluminum’s advantage is that it is corrosion resistant and strong, yet light in weight, making it potentially a suitable choice if the dock must be removed each autumn and replaced in the spring. The disadvantage is that aluminum can be pricey – as much as three times more expensive than steel.

Steel is a good choice when strength is paramount. But steel is extremely heavy and unless it’s treated, it will rust over time.

Like docks structures themselves, there are several choices available for the deck material. All come with advantages and disadvantages.

Wood deck material, like pressure treated wood, is a popular option. Wood is typically the most inexpensive decking option. Wood also tends to remain cool to the touch, even in bright sun. However, any wood will eventually rot when exposed to the elements. It can also become slippery when wet, and can cause splinters in hands and bare feet.

Composite or polymer deck material is made from a blend of wood flour, polyethylene, crushed minerals, or a polypropylene blend, and sometimes entirely from PVC. Its advantage is that it’s long-lasting, nearly maintenance-free, doesn’t splinter, and is available in a wide variety of colors. Composite deck materials are more expensive than wood, however, they can last much longer as they are not suspectable to moisture damage or rot and come in a variety of colors and textures that mimic the look of real wood.

Aluminum and other metal products are also used for dock decking. Aluminum is light in weight, yet strong and won’t rot. Aluminum and other metal decking products can be hot to the touch on a sunny day, and can be expensive.

Trusscore makes an ideal dock material made exclusively from PVC.

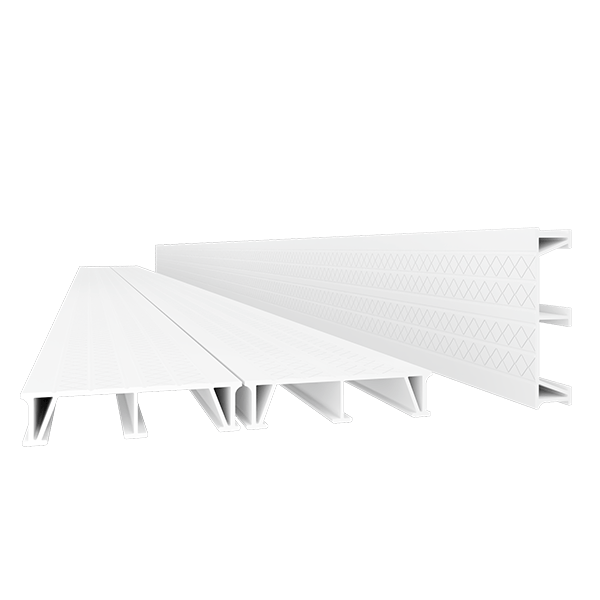

DockDeck by Trusscore has a unique open-cavity profile that makes it 40 per cent lighter in weight than composite and ensures that it doesn’t retain heat. DockDeck is impervious to water and moisture, never splinters, and is easy to install. Fasteners are hidden. It comes in two slip-resistant texture pattens, a variety of colours, and is 100 per cent recyclable. Each DockDeck board is six inches in width and it’s available in lengths of 12, 16, 20, and 24 feet. DockDeck is designed to never need maintenance or replacing.

Safe Harbor

There are plenty of boat dock designs and plans on the market. You may have your own boat dock design ideas. Before making a dock and decking decision, seek out a dock dealer or contractor who is familiar with the specific characteristics of your lake or body of water. Reputable dealers can guide you through your selection and the materials and designs best suited for your use case, your location and climate, and the body of water for which your dock is intended.

With some planning and foresight, you’ll be soon sittin’ on the dock of the bay.

Products for Docks

DockDeck

DockDeck by Trusscore is a high-performing and sustainable alternative to composite decking, pressure treated wood, and aluminum that will look its best for decades to come.

Learn More