Customer Story

Everything It’s Cracked Up To Be

How a need for longevity, durability, and hygiene led a large poultry farm to Trusscore

The Rundown

The Fisher Poultry Farm is in business for the long haul. It needed a product that would stand the test of time – and the test of hygiene – in its enormous commercial poultry barns. In theory, they could have chosen any product on the market.

Read on to find out exactly why this high-capacity poultry operation opted for Trusscore Wall&CeilingBoard over inferior alternatives like FRP or corrugated sheet metal.

The Fisher Poultry Farm

- Established in 1903

- Commercial poultry producer

Ayton, Ontario, Canada

A Search for Longevity

The Fisher Poultry Farm, located in Ayton, Ontario, Canada, has roots going back to 1903 and is a division of P&H (Parrish & Heimbecker), the giant diversified agribusiness headquartered in Winnipeg, Manitoba. When Fisher Poultry Farm’s own Kevin Weber was tasked with overseeing the construction of the first in a series of the company’s new barns, one of the company’s fundamental requirements was that the barns be durable and long-lasting.

Weber, who has been on the job at Fisher Poultry Farm for 42 years, says that in the past, poultry barn plans would typically call for the walls to be lined with ribbed metal sheeting or plywood. Some operators would instead opt to install FRP (fiberglass reinforced plastic) panels. Each of those products, however, comes with drawbacks.

The builder, Domm Construction, also out of Ayton, listened to the farm’s requirements, sized up the use-case, and promptly suggested Trusscore Wall&CeilingBoard for the barn’s interior walls and ceilings. Weber hasn’t looked back.

Installer Spotlight

Domm Construction Ltd.

Established in 1985

Avid installer of Trusscore products

Ayton, Ontario, Canada

DommConstruction.ca

Fisher Poultry Farm has 10 barns, 300,000 square feet of space, and over 500,000 hens.

That’s a lot of space, a lot of hens, and a lot of barns — each with their own demanding environment.

That’s why the farm’s operation now depends on Trusscore Wall&CeilingBoard to get the job done, each and every day.

Built to Perform

Poultry barns are enormous structures. The Fisher Poultry barns — there are 10 of them — each has 12-foot ceilings and an area of about 30,000 square feet, housing about 500,000 hens. Ventilation, airflow, and dust control within the barns are key to maintaining the health of the hens and continued egg production.

Trusscore Wall&CeilingBoard panels have a smooth, non-porous finish and tight, flush seams between interlocking panels, allowing for efficient airflow. And the precisely engineered PVC material that Wall&CeilingBoard is made from allows for resistance to chemicals and a surface that is easy to clean. Trusscore products also help prevent mold and mildew, because they are impervious to water and moisture; yet another feature that helps maintain animal health and product quality.

“I look after the operations here, and the good people that look after the money said to me, ‘Kev, make sure you build something that’s going to last.’ They were looking for 20-25 years of longevity. We’re going to get way, way longer than that from what I see. These barns are going to last.”

– Kevin Weber, Manager of Fisher Poultry Farm

“After we’re finished cleaning the barns, the Trusscore product looks like the day it was installed. How can you beat that?”

Kevin Weber, Manager of Fisher Poultry Farm

A Superior Alternative

None of the products used in the past for the interior of a poultry barn perform as well as Trusscore Wall&CeilingBoard, Weber explains. Ribbed metal sheeting, for instance, inhibits airflow within the structure. Plywood and drywall are more difficult to clean than Wall&CeilingBoard — by a long shot. And materials like plywood, drywall, and FRP (fiberglass reinforced plastic) all have a habit of swelling and degrading when they get wet, meaning all three often become a breeding ground for mold and mildew.

With all of that in mind, Trusscore Wall&CeilingBoard becomes a no-brainer on a poultry farm. The panels maintain their integrity, they won’t swell, and the product delivers unprecedented performance and longevity.

Fisher Poultry found Trusscore Wall&CeilingBoard to be the ideal solution they were seeking, so there was nothing left to do but let Domm Construction do their thing.

After Trusscore

Chicken Or The Egg? With Trusscore, It Doesn’t Matter Which Came First

Enhanced airflow. Enhanced hygiene. Enhanced biosecurity. Enhanced lighting. Enhanced longevity. Trusscore Wall&CeilingBoard has delivered for the Fisher Poultry operation in every way possible.

Thanks to these poultry panels, their barns are easier to clean and more cost-efficient, generating more revenue for their owners and more food for society’s tables.

“Trusscore Wall&CeilingBoard has handled everything we’ve thrown at it. I can't say it enough how easy it is to keep things in good shape. By using Trusscore, we don't have any worries.”

– Kevin Weber, Manager of Fisher Poultry Farm.

Trusscore: The Premier Solution for Poultry Facilities

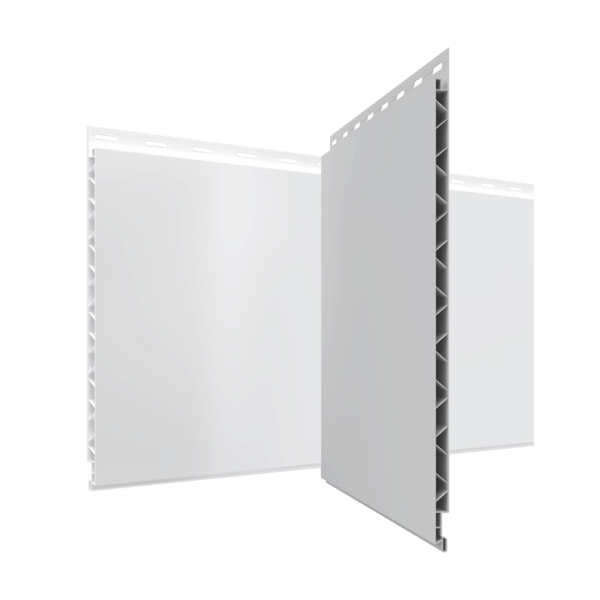

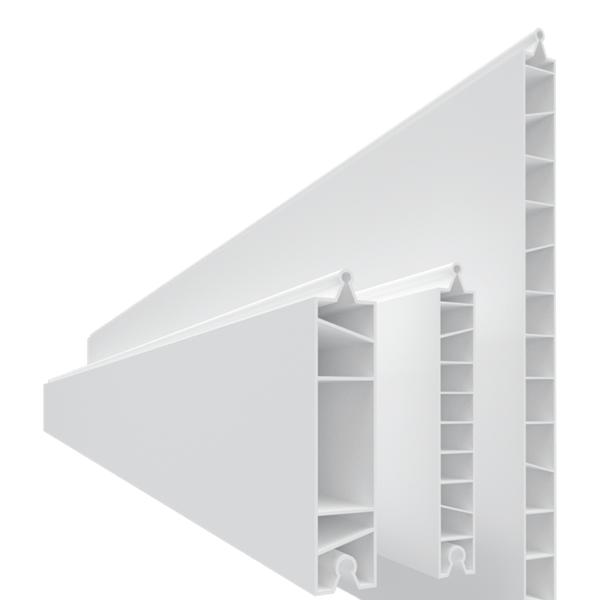

Wall&CeilingBoard

Trusscore Wall&CeilingBoard are interlocking, interior PVC wall and ceiling panels that are lightweight, low maintenance, and outperform products like drywall and FRP.

Learn MoreNorLock

NorLock by Trusscore are durable freestanding, interlocking divider planks for interior walls, non-load bearing partitions, and penning.

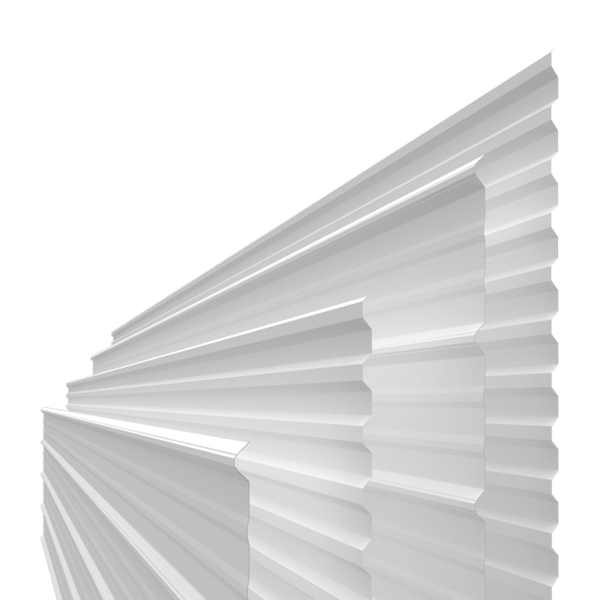

Learn MoreRibCore

RibCore by Trusscore are high-strength PVC corrugated panels that are durable, cost effective, and easy to install and maintain.

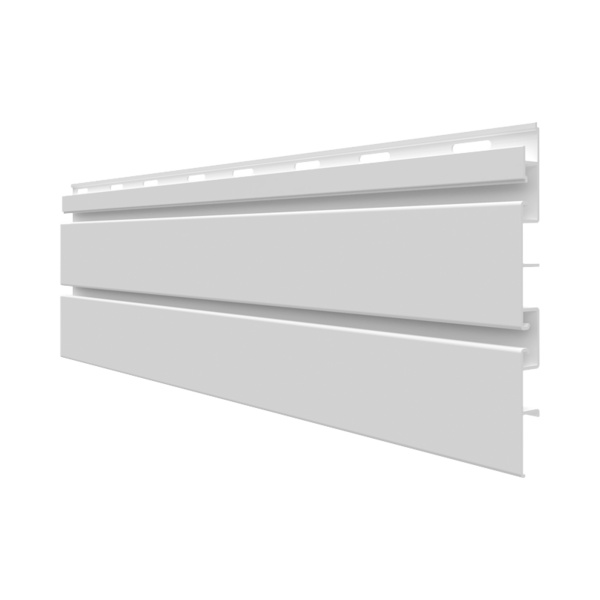

Learn MoreSlatWall

Trusscore SlatWall is a high-strength, on-the-wall organization system that’s easy to install and seamlessly integrates with Trusscore Wall&CeilingBoard.

Learn MoreMore to Explore

Strength & Durability

Industry-leading strength designed to withstand the toughest applications

Trusscore wall and ceiling panels provide unparalleled strength and durability.

Learn MoreMoisture & Water Resistant

Extend the life of your space with water-resistant wall panels

Long-lasting protection against moisture and water to keep your space mold- and mildew-free.

Learn MoreCleanability

Keeping it clean with washable wall panels

Easy to clean wall and ceiling panels for residential, commercial, and agriculture spaces.

Learn More